rockwell hardness test b range of values|rockwell c hardness chart : distribution Calculating the depth differential, or B – A value — this figure then transfers to the Rockwell C scale chart and becomes the Rockwell hardness number. The Rockwell hardness number is not the same as the calculated depth differential .

WEBBlumenau - SC. A empresa CENTRAL AILOS, com a razão social COOPERATIVA CENTRAL DE CREDITO AILOS, opera com o CNPJ 05.463.212/0001-29 e tem sua .

{plog:ftitle_list}

web10 de dez. de 2022 · Resumo. Ao entrar no set de filmagens, Cha Hong, uma escritora freelancer escuta, “ela agora é sua responsabilidade”. Quando se torna assistente de .

Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your . The Rockwell scale is a hardness scale based on indentation .

rockwell steel hardness chart

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges . The Rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the Rockwell formula. The resulting value is then translated to the .Calculating the depth differential, or B – A value — this figure then transfers to the Rockwell C scale chart and becomes the Rockwell hardness number. The Rockwell hardness number is not the same as the calculated depth differential .

There are two main scales used in the Rockwell test: the Rockwell HRC scale (uses a diamond cone indenter) for harder materials and the Rockwell HRB scale (uses a ball indenter) for softer materials. The equations for calculating .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers . This results in hardness values in the theoretical range of 0 (full indentation depth to 0.26 mm) to 130 (no indentation depth) when using carbide balls. When using a carbide ball for hardness testing, a main distinction is .Main loads. The Rockwell hardness test utilizes 1 of 6 different main loads: 15 kgf, 30 kgf, 45 kgf, 60 kgf, 100 kgf, or 150 kgf. In total, this gives 30 different Rockwell scales.

The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell . Different series of aluminum alloys have different hardness values; for example, there are differences between the hardness of 7075 aluminum alloy and 6063 aluminum alloy. Furthermore, the hardness of .

In the Rockwell hardness test, an indenter is pressed into the material. . This results in hardness values in the theoretical range of 0 (full indentation depth to 0.26 mm) to 130 (no indentation depth) when using .The Rockwell test is applicable to a wide range of part sizes. Sheet metal as thin as 0.006 inch can . No Rockwell hardness value is specified by a number alone. It must always be prefixed by a letter signifying the value of the major load and type of penetrator (e.g. HRC 35). ADefinition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: HRE 1/8” diameter tungsten carbide ball indenter, 100 kgf major loadSteel Hardness conversion calculator: Brinell Hardness HB: Rockwell C - HRC: Rockwell B - HRB: Vickers - HV : Enter a figure into any of the fields and click calculate, the nearest values in each scale is shown, or zero if out of range. Values are approximate and for guidance only.

The scope of use of every test is different but the most common method is Rockwell. The Rockwell hardness B scale is used for soft or mild metal materials. + 86 755 61301520; [email protected] . The Rockwell hardness test measures the eternal depth created by a specific indenter and a specific test force. . The range of the scale lies .Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y

This article explains the procedure to perform the Rockwell hardness test on metals. Rockwell Hardness Test Procedure. The Rockwell hardness test employs the principle of differential-depth method. During the test, the indenter of the equipment is forced to make a residual depth on the test specimen.

The various indenter types combined with a range of test loads form a matrix of Rockwell hardness scales that are applicable to a wide variety of materials. Rockwell B and Rockwell C are the typical tests in this facility. The Rockwell B penetrator is a 1.59mm (1/16 inch) diameter tungsten-carbide ball and the major load is Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The .The Rockwell Hardness Test presses a steel or diamond hemisphere-conical penetrator against a test specimen and measures the resulting indentation depth as a gage of the specimen hardness. The harder the material, the higher the HR reading. . The hardness value is below the acceptable range of the particular hardness scale. >>

Total test force/N: Constant K: Hardness range: application examples: A: Diamond circular dimension: 100: 500: 600: 100: 60~85: High hardness thin parts and cemented carbides: B: φ1.588mm steel ball: 900: . It is important to note that Rockwell hardness values obtained from different scales are not comparable. 4. Vickers hardness 1. PrincipleThe Rockwell hardness test involves indenting the surface of a material with a diamond cone or steel ball indenter and measuring the depth of the resulting indentation. . Provides a wide range of hardness values: The Rockwell hardness test provides a wide range of hardness values, which makes it suitable for testing a variety of materials. .

rockwell scale comparison chart

Several different Rockwell scales are used for various materials and hardnesses. The most common are the Rockwell B and Rockwell C scales. The Rockwell B system incorporates a 1/16 th inch diameter steel ball, with a load of 100kg for softer materials such as aluminium alloys and materials of similar hardness. Harder materials such as cast irons are . If the hardness exceeds this range, use Rockwell hardness A scale (HRA). If the hardness is below this range, use Rockwell hardness B scale (HRB). The upper limit of Brinell hardness is HB650; it cannot exceed .

The hardness of 316 stainless steel typically ranges from 70 to 90 HRB (Rockwell B) in its annealed condition. When subjected to cold working or other processes, its hardness can increase, reaching about 30 to 40 HRC (Rockwell C). The exact hardness can vary based on specific processing methods and the material’s condition.Rockwell Hardness Test. The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in the R, L, M, E and K scales. . As a result, BHN is usually quoted as a range of values (e.g. 210 to 245, or 210-245) rather than as a .

The Rockwell hardness test is appropriate for hardness values ranging from 20-70HRC. If the hardness of the sample is less than 20HRC, it is recommended to use the HRB scale as the sensitivity of the indenter decreases with increased pressure on the conical part. . The Rockwell hardness test is known for its ease, speed, and minimal .Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for

The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520 . These indenters are unique to the Rockwell hardness test alone. Test Load – The range of loads and the combination of initial minor loads and final major loads also distinguishes the Rockwell method from other test methods .The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a diamond indenter to make an indentation which is measured and converted to a hardness value. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be .The equations for calculating Rockwell B (HRB) and Rockwell C (HRC) hardness values are as follows: Rockwell B (HRB) Hardness: = 130 – (P/A) Rockwell C (HRC) Hardness: = N – d; Where: HRB is the Rockwell B hardness value. P is the depth of the indenter penetration under minor load; A is a constant factor specific to the scale; HRC is the .Brinell and Rockwell Hardness Conversion Table Chart. These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship .

rockwell hardness scale explained

visual studio 2013 test impact analysis

How To Operate The Analog Rockwell Hardness Tester ; Cylindrical Correction Chart; Hardness Conversion Chart - Rockwell "B" Hardness Range; Hardness Conversion Chart - Rockwell "C" Hardness Range; Hardness vs Minimum Thickness Chart; Rockwell Scale-Indenter-Load Chart; Contact Us. About Us; Store Policies; Blog

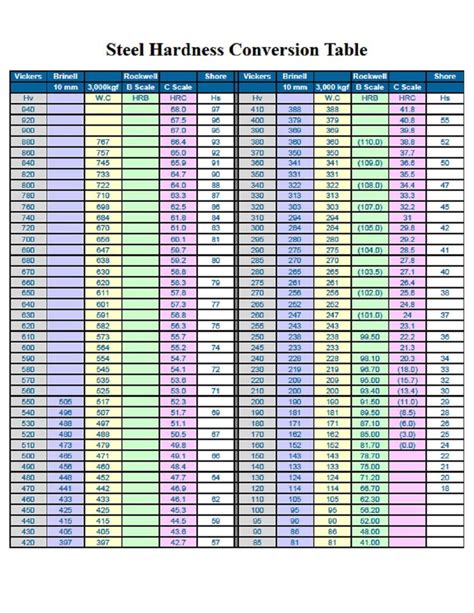

1.2 Conversion Table 2 presents data in the Rockwell B hardness range on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial . 1.12 Conversion of hardness values should be used only when it is impossible to test the material under the conditions . 3.1.3 Rockwell Hardness—Test Method . A recorded hardness number of 63HRC signifies a hardness of 63 on the Rockwell C scale. Higher values indicate harder materials such as hardened steel or tungsten carbide. These can have HRC values in excess of 70HRC. Rockwell test forces can be applied by either closed-loop load cell or traditional deadweight systems.

visual studio 2015 test impact analysis

visual studio test impact analysis

WEBRelação dos números mais sorteados na Mega Sena em 2023, desde o concurso número 2551, sorteado em 04/01/2023 até o último, concurso 2670, realizado em 31/12/2023. Neste período a Mega Sena teve 120 .

rockwell hardness test b range of values|rockwell c hardness chart